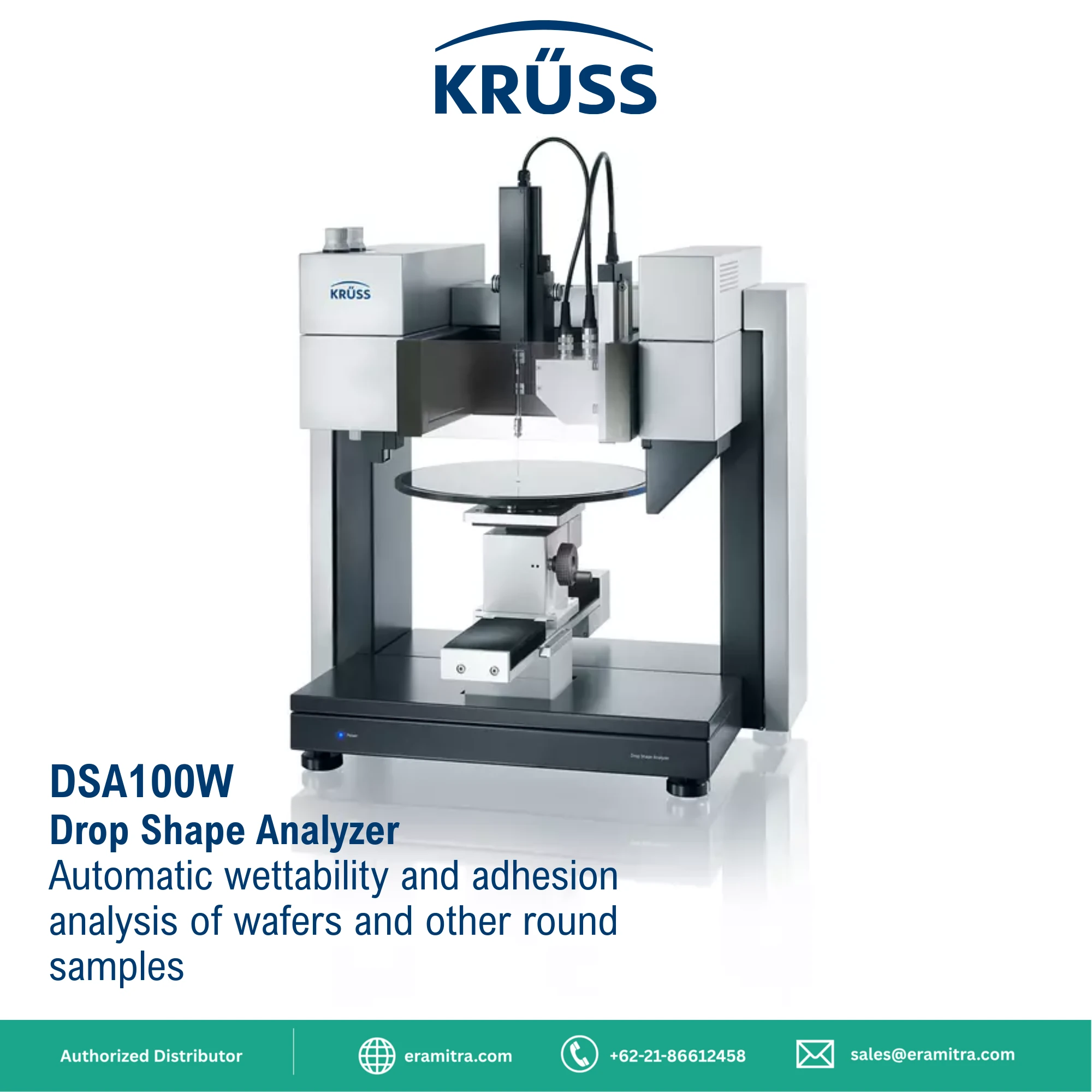

Drop Shape Analyzer

Automatic wettability and adhesion analysis of wafers and other round samples

The Wafer configuration of the DSA100 Drop Shape Analyzer is geared towards the automatic, standardized quality control of wafer surfaces and other round samples. The instrument precisely determines the homogeneity of the cleaning of a surface based on the contact angle. It also enables coatings to be characterized, for example by differences in wetting of exposed and unexposed photo varnish.

Applications

-

Characterization of the cleaning and coating homogeneity of wafers

-

Adhesion evaluation between wafer and coating

-

Wetting investigation of exposed and unexposed photo varnish

-

Ideal for analyzing other round samples, e.g. hard drives or brake disks

Measuring methods

- Contact angle of a drop on a solid surface

- Contact angles of two drops dosed in parallel

- Automated position-dependent contact angle measurement and evaluation

- Contact angle using a gas bubble beneath a solid surface in a liquid

- Surface free energy of a solid using contact angle data

- Surface tension using the curvature of a perfectly symmetrical drop on a circular sample pedestal

- Roll-off behavior and advancing/receding contact angle of a drop on a tilted surface

- Carrying out a measurement up to 20 consecutive times and displaying the results together

- Remote control of ADVANCE for integration in custom-designed, complex automations

- Measuring the recently receded contact angle to characterize dewetting behavior

Measuring results

-

Static contact angle

-

Advancing and receding contact angle

-

Contact angle using a bubble in a liquid

-

Surface free energy (SFE) according to the following models: Owens-Wendt-Rabel-Kaelble (OWRK), Fowkes, Extended Fowkes, Van Oss & Good (Acid-Base), Schultz, Wu, Zisman, Equation of State

-

Position-dependent contact angle and SFE

-

Temperature